Outline

Future

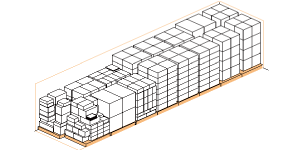

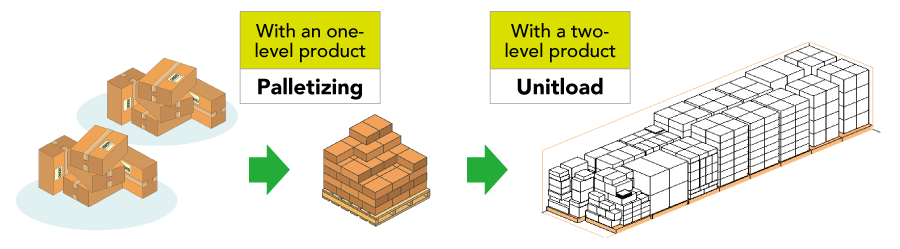

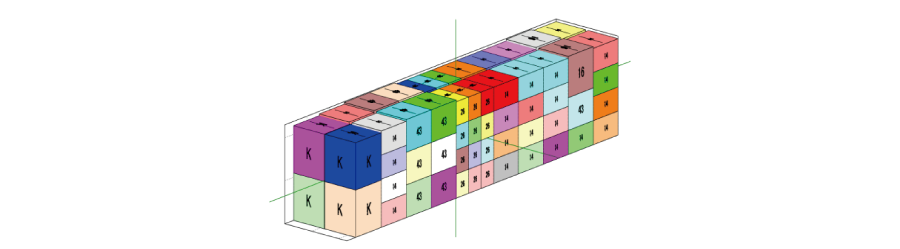

- Result with a product with high loading efficiency can seen simply.

The load of several different form and sizes.

Calculates several kinds may be stacked and a transporter may become the minimum under conditions.

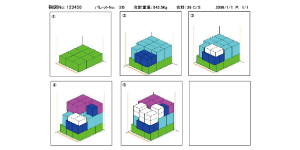

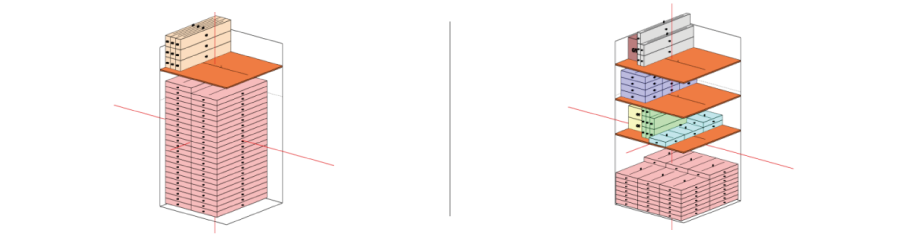

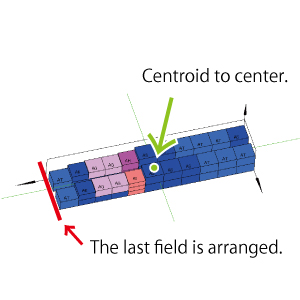

- Since the result with loading is calculated taking a centroid location into consideration in order to prevent collapse of cargo piles, it leads to improvement in the quality of goods in transit.

By 3D display and print function, centroid location and fixed material can see necessary location, and lead to accident prevention.

- Use number of a container is drawn according to the loading amount of resources.

- Calculation with a product which selected the size of two or more containers are possible.

- The size of a container can be changed freely.

It is possible to observe and calculate with a product on various sizes.The conjugation to palette box container track are possible.

Result

- If it is not the site experience person in charge who became skilled in business with a product, a clerk can draw the result with a product in which it is difficult to draw.

Thereby, activity schedule can be constructed now based on the result with a product calculated beforehand. - The result with a product optimal in an instant can be drawn on an lot of amount of resources.

This prevents order of a useless container. The high loading result of quality which prevented collapse of cargo piles is utilizable as written directive to site.

Functional explanation

Cargo data taking-in feature and input feature

- Transporter information (example container) and cargo data information are taken in or entered.

(length / width / height / weight / quantity) - “Paste” feature is carried in the cargo data input screen.

The information (length / height / weight / quantity) copied in Excel can be pasted on a cargo data input screen.

Optimized calculation

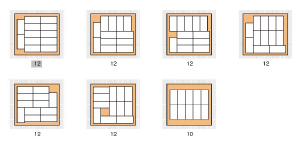

- Two or more engines with product set by the container track / palette / box stuffing are carried.

- It is possible to select the multiple selection of container and different container of type at the same time, and to carry out optimized calculation.

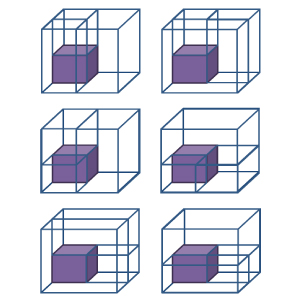

3D arrangement confirmation

- The calculated result is displayed by 3D picture.

3D picture can be moved with a mouse. - It can work at the site which load performs, checking the attention part and centroid location of collapse of cargo piles.

Manual layout change

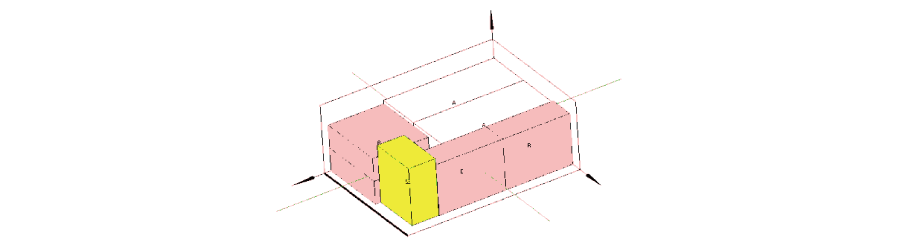

- It is a feature which carries out the manual arrangement retouch of the result which the engine with loading calculated by a person’s in charge conclusion.

Moving 3D image with mouse and confirming safety to do for manual arrangement are possible. - Freight movement between containers :

Freight movement between two or more containers are possible. - Manual arrangement:

The exact arrangement in 1 container is possible.

Movement between containers

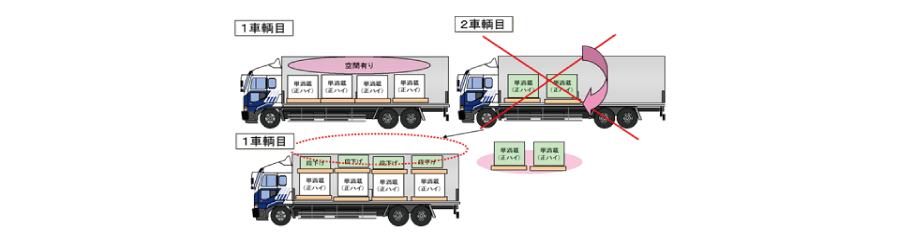

- It is the feature to move a cargo of 2D screen to other tracks, checking a loading situation by 3D drawing.

- It is used when canceling cargo of the container which was being loaded, and making it add from other tracks.

- It calculatte automatically,and also can link between a manual relocation function.

It works only under the specific track to which the load was moved.

Movement between containers by a cross tabulation

- It is feature to display arrangement situation of container and load in cross tabulation, move the number of display loads to other containers by mouse.

Specific container can be made to collect flexibly a product group to make it move collectively. - When two or more containers become the same loading process, 1 container loading image can be copied.

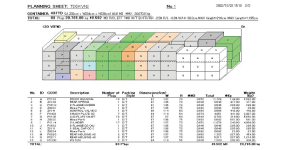

Product attached chart printing

- The result calculated by the engine can be output,and it can be changed by the manual relocation function.

- The output of a loading image figure and loading details is possible.

- It is utilizable as container vanning figure or vehicles shipping written directive.

Result output function

- Loading details of a container unit is TXT form or CSV data output can be carried out.

- The Excel output of the loading details of a container unit can be carried out.

Loading engine (algorithm)

Conjugation Example

- Automatic arrangement and the data output of the shelf set by the quantity of the conjugation same products of the space in JITBOX (Car)

- Track stacking two levels

It is considered as conjugation between a track space, and the paragraph of automatic corresponds.

- Cooperation with WMS

Rationalization of a container box (outer packaging)

- Two rows loaded.

Improvement in a loading rate to a container

Outline

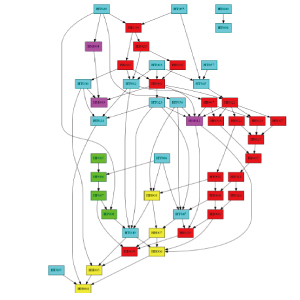

The algorithm can draw the result early and correct in large quantities than man.

However, when intuitive and it focuses only on immediate business, it is difficult to greater than man.

The algorithm carried in vanning master is using the following three algorithms properly for every scene, It is close to intuition of man and flexible high accuracy is achieved.

And our company which is a specialist in a logistic adjusts the algorithm which draws the realistic solution in consideration of an actual site according to a matter.

Heuristics

gradually space selection

It is close to intuition of man, and a good result is drawn about immediate loading and calculation speed is quick.

However, the result of having gazed at the whole cannot be drawn.

⇒ Space selection to specific container

Meta-heuristics

equalization

The directivity which should progress from a vast quantity of data can be found out.Useless calculation is excluded by memorizing the found-out calculation.

⇒ Equalization of load on consideration of the prevention from collapse of cargo piles, and all the containers

Strict solution

BOX selection

Although the guaranteed solution is drawn, it is inapplicable to 10% of the whole.

⇒ Loading of the final stage

How for installation to advance

How to advance a phase unit

Investigation

(logistic consulting)

Investigation report about test simulation and loading data about cost effectiveness based on an actual result ( office management cost and the locistic cost, the logistic cost in connection with transport)

It unites and is a hearing about an application situation.

▼

Interface /

mounting confirmation

The problem on interface or mounting is checked using sample software.

The offer process is examined according to demand.

▼

Requirement definition

In addition to a basic function, in consideration of the freight characteristic and site application, it scrutinizes what kind of feature, constraints are necessary.

▼

Configuration/customization)

Parameter setup and an algorithm are customized based on a requirement definition.

▼ △

Tuning

It brings close to real employment by parameter tuning, having a processing result checked.

▼

Evaluation with your system

The inclusion and evaluation to the logistic simulation tool of your company are performed.

It performs in simultaneous parallel.